Subtotal ₹0.00

Demand and supply are the driving forces behind everything in the trucking industry. They determine how many loads are available, what freight rates look like, and how easy or hard it is to find work. In this bonus edition, we’ll help you understand what causes demand, why it can increase or decrease, and how that affects your business as a carrier, broker, dispatcher or a shipper.

What Causes Demand in the Trucking Industry?

Demand in trucking refers to the need for transportation services—specifically, the need to move goods from one place to another. Several factors influence demand, including:

- Consumer Spending:

- When people buy more goods, especially online or from stores, there’s a higher demand for transportation to move those products from manufacturers to warehouses, and then to stores or directly to consumers. This is a key driver of demand in the trucking industry.

- Economic Conditions:

- A strong economy generally means more production, more sales, and therefore more demand for trucking services. Conversely, in a weak economy, businesses produce and sell less, leading to a decrease in demand for transportation.

- Seasonality:

- Certain times of the year naturally have higher demand for trucking services. For example, during the holiday season, there’s a surge in consumer spending, leading to increased demand for transporting goods. Agricultural seasons also create spikes in demand when crops need to be moved.

- Business Inventory Levels:

- When businesses expect higher sales, they increase their inventory levels, which boosts demand for transportation. However, if businesses are overstocked or anticipate lower sales, they might reduce their inventory purchases, leading to a drop in demand.

- Global Trade and Supply Chain Disruptions:

- Events like natural disasters, pandemics, or geopolitical tensions can disrupt global supply chains, affecting the flow of goods and altering demand for transportation services. For example, a disruption in manufacturing in one part of the world might reduce the need for trucking services to transport those goods elsewhere.

What Causes Demand to Increase?

- Economic Growth:

- When the economy is growing, businesses produce more, and consumers spend more. This growth leads to an increase in demand for trucking services as more goods need to be moved.

- Consumer Confidence:

- If consumers are confident about the economy, they tend to spend more, leading to higher demand for products and, in turn, transportation.

- Increased Production:

- When manufacturers ramp up production due to high demand for their products, there’s an increase in the need for trucks to transport raw materials to factories and finished goods to market.

- Holiday and Seasonal Peaks:

- The holiday season, back-to-school periods, and agricultural harvests typically lead to spikes in demand as retailers stock up and goods need to be moved quickly.

What Causes Demand to Decrease?

- Economic Downturns:

- During a recession or economic slowdown, businesses and consumers spend less. This reduced spending leads to lower production and fewer goods needing transportation, which decreases demand.

- High Inventory Levels:

- If businesses already have large amounts of inventory, they might reduce their orders, leading to fewer shipments and lower demand for trucking services.

- Reduced Consumer Spending:

- When consumers cut back on spending—whether due to high prices, economic uncertainty, or rising interest rates—demand for goods, and consequently transportation, drops.

- Supply Chain Disruptions:

- Events like natural disasters, strikes, or global trade issues can slow down production and reduce the flow of goods, leading to a drop in transportation demand.

Why Load Boards, Brokers, and Shippers May Not Have Loads for Carriers

When demand decreases, the first places you might notice this are load boards, brokers, and shippers. Here’s why:

- Fewer Goods to Move:

- If demand is low because of economic downturns or high inventory levels, there simply aren’t as many goods that need to be transported. This means load boards and brokers have fewer loads to offer carriers.

- Increased Competition:

- When there are fewer loads available, more carriers are competing for the same jobs. This competition can make it harder to secure loads, especially if you’re relying on load boards.

- Lower Freight Rates:

- With fewer loads and more competition among carriers, freight rates tend to drop. Brokers and shippers know they can get lower bids from carriers desperate for work, which pushes rates down further.

- Seasonal Lows:

- Outside of peak seasons, demand naturally drops, leading to fewer available loads. For example, after the holiday rush, there’s often a slowdown in consumer spending, which reduces the need for transportation.

How This Impacts You and What You Can Do

For Carriers:

Understanding the Impact: When demand drops, you may find fewer loads on the boards, and the rates you can charge may decrease. High competition means you’ll need to work harder to secure jobs and maintain profitability.

- Action Steps:

- Plan for Seasonality: Capitalize on peak seasons by taking on as much work as possible and saving for slower periods.

- Diversify Your Client Base: Build relationships with multiple brokers and shippers to secure more consistent work.

- Monitor Economic Indicators: Keep an eye on trends like consumer spending and inventory levels to predict demand changes and adjust your operations accordingly.

- Adjust Pricing Strategically: Be flexible with your pricing to remain competitive during low-demand periods, but ensure your rates cover your costs.

- Build Strong Relationships: Cultivating long-term relationships with brokers, shippers, and even direct clients can help you secure steady work, even when the market is slow. Reliable partners are more likely to give you consistent loads and favorable rates, helping you weather low-demand periods.

For Brokers:

Understanding the Impact: As demand fluctuates, so does your ability to find and offer loads. High demand makes it easier to find freight, but low demand means you may struggle to provide work for carriers at profitable rates.

- Action Steps:

- Secure Capacity Early: In high-demand times, lock in transportation capacity to ensure you can meet your clients’ needs without overpaying.

- Negotiate Rates Wisely: Use your knowledge of market conditions to negotiate rates that are fair for both carriers and shippers, ensuring long-term relationships.

- Adapt to Seasonal Fluctuations: Anticipate when demand will peak or drop, and adjust your strategies to maintain steady business.

- Leverage Economic Trends: Stay informed about economic indicators that affect demand, such as interest rates and consumer confidence, to better serve your clients and optimize your operations.

- Build Strong Relationships: Develop and maintain strong ties with reliable carriers. In times of low demand, these relationships will help you secure the capacity you need without having to scramble for solutions.

For Dispatchers:

Understanding the Impact: Demand affects how many loads you can assign and the rates carriers can charge. When demand is low, optimizing routes and ensuring efficiency becomes even more critical.

- Action Steps:

- Optimize Routes: Use technology and planning to reduce empty miles and make the most of available loads, especially during low-demand periods.

- Plan for Capacity Changes: Understand when demand is likely to increase or decrease and adjust your scheduling and load assignments accordingly.

- Communicate with Carriers: Keep carriers informed about market conditions and help them understand when and where they might find better-paying loads.

- Maximize Efficiency: In times of low demand, every mile and minute counts. Streamline your operations to ensure that every trip is as productive as possible.

- Build Strong Relationships: Establishing trust and open communication with carriers can make your job easier when demand is low. Strong relationships mean better cooperation, more flexible arrangements, and a smoother operation overall.

For Shippers:

Understanding the Impact: Demand and supply affect how much you’ll pay for transportation and how easily you can find carriers to move your goods. When demand is high, you might face higher costs and tighter capacity.

- Action Steps:

- Lock in Long-Term Contracts: During periods of high demand, secure long-term agreements with carriers to stabilize your transportation costs and ensure capacity.

- Manage Inventory Wisely: Adjust your inventory levels based on demand forecasts to avoid overstocking or understocking, both of which can impact your shipping needs.

- Stay Informed: Monitor demand trends and economic indicators that influence transportation costs. Use this knowledge to make informed decisions about when to ship and how to budget for logistics.

- Build Strong Relationships: Maintaining good relationships with reliable carriers can help you ensure that you have the capacity you need, even during peak times. Carriers who know and trust you are more likely to prioritize your loads.

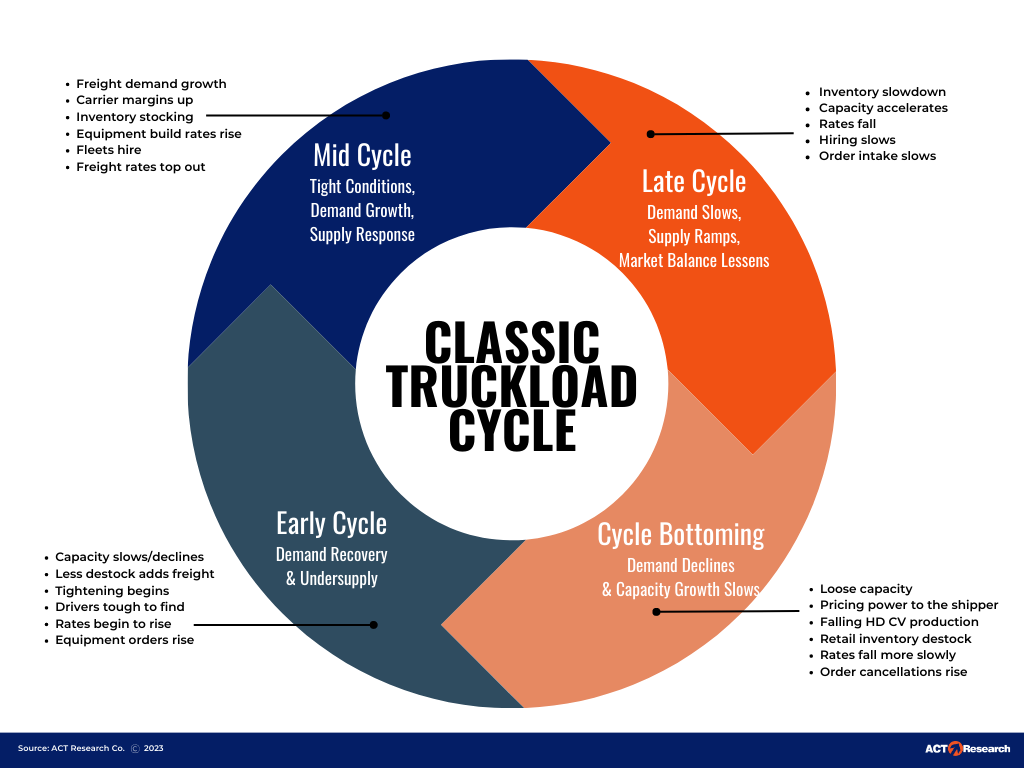

The Supply Side

The carrier (trucking company or other transportation provider) represents the supply side. Click here for insight on the supply side:

Conclusion

Understanding how demand and supply work—and what causes them to rise and fall—can help you make smarter decisions in the trucking industry. Whether you’re a carrier, broker, dispatcher, or shipper, knowing how these factors impact load availability and freight rates is crucial for staying competitive and profitable. By planning ahead, diversifying your strategies, building strong relationships, and staying informed, you can navigate the ups and downs of the market with ‘confidence and success’ – where preparation and opportunity meet.